A hub for innovation: Texas A&M’s Makerspace empowers students to bring ideas to life

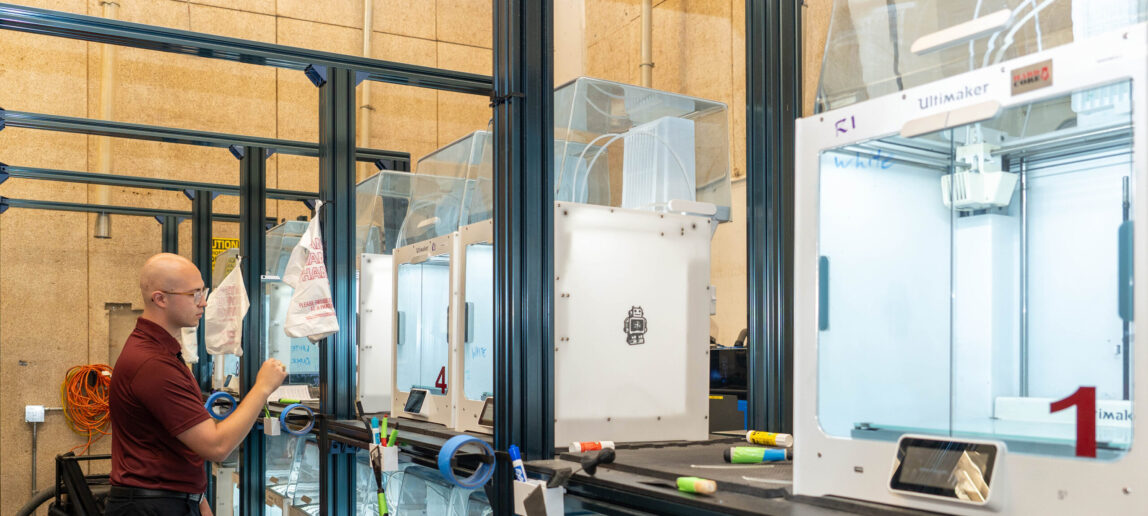

From laser cutting to 3D printing, the Innovation Hub-Makerspace at Texas A&M University is designed to be a vibrant hub for creativity. Open to all students, this state-of-the-art facility offers a unique environment designed to foster innovation, learning and hands-on development.

The Makerspace provides an opportunity for academic and research pursuits. Undergraduate research students, like Roman Venegas, have found the Makerspace to be an invaluable resource in their studies.

Venegas, who is majoring in electrical engineering, utilizes the Makerspace to prototype and develop his projects.

He values the space for its welcoming environment, particularly for creative individuals. “You can just come in and start working on whatever you’re thinking about,” Venegas said. “That’s why I really enjoy it.”

Venegas embarked on his journey into 3D printing while working on his first research paper on Radio Frequency (RF) cable traps. He frequently used the Makerspace for prototyping his ideas and models, sparking his interest in the technology. He quickly realized the immense potential 3D printing had to offer, especially in its influence on his work as an electrical engineer.

“3D printing has really changed the way I approach electrical engineering,” Venegas explained. “It’s given me an outlet for creativity and turned my mindset from ‘I can’t do this’ to ‘I can make this.’”

Venegas shared several of his 3D-printed prototypes, crafted from Nylon12, a material used exclusively with Selective Laser Sintering (SLS) 3D Printing. He plans to further refine these models by making them more compact and efficient. Nylon was his material of choice for its precision and detailed printing results.

“I couldn’t get this level of accuracy with a plastic filament printer,” Venegas explained. “The nozzle is too big to print something as small as a dovetail key. But with nylon, it holds together nicely, doesn’t slip out too easily and is very accurate and precise.”

The collaborative environment at the Makerspace also plays a significant role in Venegas’s work. The open and friendly atmosphere makes it easy for him to share ideas and receive honest, constructive feedback.

“The environment here is inviting and supportive,” Venegas said. “I feel confident sharing my ideas and know that I’ll get genuine feedback.”

He encourages anyone using the Makerspace to seek feedback from the staff on their designs, emphasizing that “it’s a great way to get unbiased opinions and enhance how you communicate your research.”

In addition to his work at the Makerspace, Venegas is an undergraduate researcher for both Dr. Arya Menon, assistant professor in electrical and computer engineering, and Dr. Mary McDougall, professor in biomedical engineering.

In Dr. Menon’s lab, he is implementing Field Programmable Gate Arrays (FPGA) to perform digital signal processing (DSP) for a cognitive radar they plan to build.

Meanwhile, in Dr. McDougall’s lab, he is working to have his previous paper published in the Institute of Electrical and Electronics Engineers (IEEE) Journal of Translational Engineering in Health and Medicine.

Balancing these demanding roles requires careful planning, and Venegas has adopted a disciplined approach, utilizing a planner and a strict schedule to manage his time effectively.

The Makerspace offers a wide array of tools and services to support nearly any project. Among the offerings are various 3D printing technologies, including fused deposition modeling (FDM), stereolithography (SLA) and SLS printers, along with laser cutting stations, workbenches equipped with non-power tools and design computer stations.