Hands-On History: Exploring Galveston’s Seawall in 3D

Visitors with visual impairments can now hold, touch, and experience the Galveston Seawall at the Galveston County Museum, following a 3D printing and design collaboration with the College of Architecture’s Innovation Hub-Makerspace at Texas A&M University. This project introduces a new dimension to the museum, enhancing accessibility for all.

The idea to add a scaled, 3D printed model of the seawall to the museum originated with Jodi Wright-Gidley, director and curator of the Galveston County Museum, and Kathleen Maca, a local historian and author who leads the museum’s tours.

Wright-Gidley said she is a long-time advocate for accessibility in museums.

“We want everyone to enjoy and learn about the history of our area,” she said. “Reading and looking at historic images and artifacts is just one way to learn in a museum. “Tactile learning often creates a better understanding and longer-lasting memories.”

A Seawall Replica

When chatting with Maca one day, Wright-Gidley said the subject came up about how it would be nice for visitors to be able to better experience and “feel” the Seawall. One of the largest infrastructure projects of its time, the Seawall plays a huge role in the cities’ history, having been built after the most fatal natural disaster in U.S. history: the Great Galveston Hurricane of 1900.

At that time of the disaster, Galveston was a key deep-water port between New Orleans and Mexico. In the aftermath of the hurricane, city leaders and the Army Corps of Engineers developed a plan to construct a seawall, which has since provided essential protection for the city.

To create a scaled and accurate copy of the seawall, Wright-Gidley turned to an online search for 3D print file design help. She stumbled upon the Texas A&M Innovation Hub website and reached out.

Bringing Design to Life

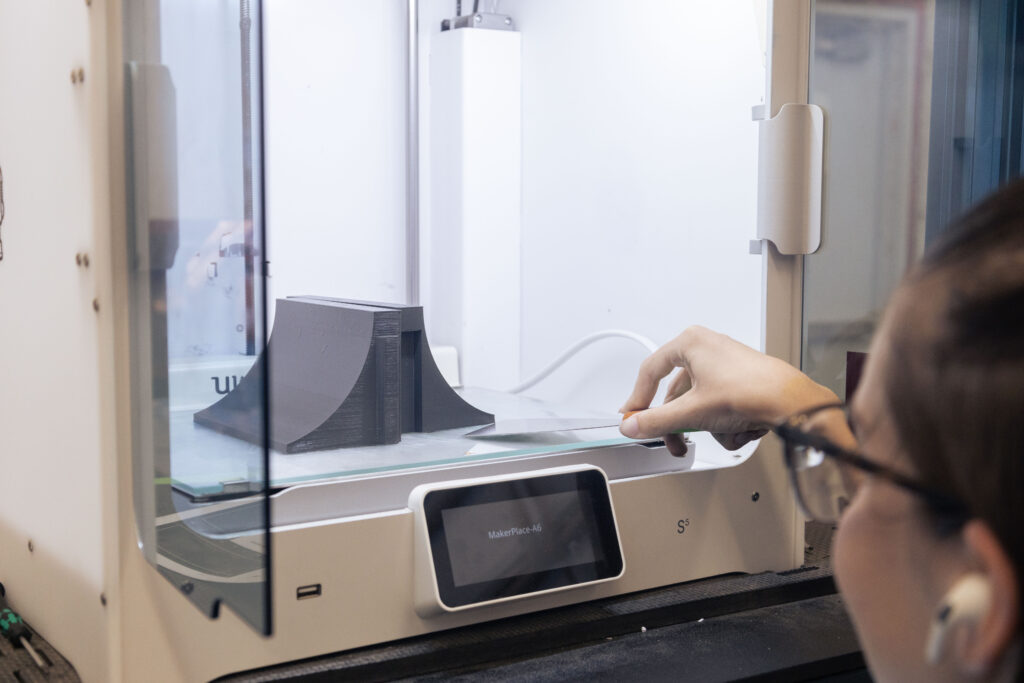

Wright-Gidley provided detailed dimensions of the Seawall from the museum’s archives, which Nipper was able to convert into a detailed digital 3D design model. The main challenge, he said, was to create a model large enough to show detail, but small enough to be held and handled easily and that could be printed on any standard 3D printer.

“The tricky part was the length of the seawall being 60 feet long, converting the scale down made the wall about 12 inches long,” said Nipper. “I knew most 3D printers aren’t equipped with that large of a build area, so what I suggested was to split a wall section in half, to 6 inches, yet keeping the tongue and groove alignments on each side so that the prints would still mimic the full scale of the seawall but be in two parts.”

“We’re always happy to help bring projects and ideas to life,” said Alex Nipper, program coordinator for the Innovation Hub-Makerspace. “All of our shops are equipped with tools, equipment, and experts to help anyone in or outside Texas A&M with projects they might have.”

The final model consists of two interconnecting pieces, featuring ridges and grooves that replicate the structure of the actual seawall. After the Seawall was digitally modeled and test-printed in College Station, Wright-Gidley was able to have it printed locally in Galveston. It is now on display at the museum for people to engage with.

“It turned out better than I imagined,” said Wright-Gidley.

“Our visitor center is also planning educational presentations and events that will incorporate the model,” she said. “We hope it will allow museum visitors to gain a better understanding of the shape of the seawall, as well as the importance of its engineering and history.”

Future Plans

The director said Galveston County Museum has plans for future work with 3D printed models to expand there for all visitors. They also aim to find other ways to incorporate hands-on learning through these physical models.

“We have been coming up with all kinds of ideas for future 3D models. We could pick an artifact that is very fragile—one that we wouldn’t want people to actually handle—but they could hold a 3D model version of it,” Wright-Gidley said. “Or maybe the next model we create will demonstrate the grade-raising, which is another fascinating part of Galveston’s history that involved physically raising the elevation of 500 city blocks.”

For more information on Galveston and its history click here.